DIGITAL VACUUM WAX INJECTOR (DVWI)

■ HighFilling Ability

Fillingability is very high since wax is injected after the inside of a rubber mold is vacuumized. A wax pattern with high filling ability is provided for both thin and small materials.

■ Settingof Small Time Unit

Settingof small time unit is possible. The vacuum time can be set down to 1/100 secondand the injection time can be set down to 1/10 second.

■ TemperatureAccuracy of ±0.2℃

Sincetemperature control by the wax tank heater is independent from temperaturecontrol by the nozzle heater, the temperature of wax can be set with anaccuracy of ±0.2℃.

■ StandbyTimer with Heating on

Theheating start time can be set at 1-99 hours. It is possible not only to saveelectric costs but also to enhance working efficiency by dissolving wax justbefore the start time of work.

■ CompactDesign

Thedouble tank comprises the vacuum tank and the wax tank in a concentric circle, and the unit is compactly designedto be easily installed anywhere.

■ HeightAdjuster Debut!!

Itis easy to change the height.

Technical data

|

Power supply |

Japan and US :single phase AC 100/ 115 V±10%, 50/60 Hz |

|

foreign countries excluding US:single phase |

|

|

Power consumption |

450 VA (maximum)/ fuse: 5A |

|

Heater power consumption |

band heater: 100/115 V-300 VA,230V-300VA |

|

cartridge heater: 100/115 V-40 VA,230V-40VA |

|

|

Temperature indication range |

40.0~99.9 ℃ (103~210 °F) |

|

Temperature setting range |

40.0~90.0 ℃ (103~193 °F) |

|

Setting range of primary pressure |

10~220 kpa |

|

Vacuum timer setting range |

0~9.99 seconds/0~99.9 seconds |

|

Injection timer setting range |

0~99.9 seconds/0~600 seconds |

|

Heating start timer |

0~99 hours |

|

Wax capacity |

around 3 kg |

|

Air supply source |

0.40~0.70 MPa/ pressure gauge: 0~0.2 MPa (0~2 kgf/cm2) |

|

External dimension |

450 (width)×310 (depth)×450 (height) mm |

|

Weight |

around 15.5 kg |

DIGITAL AUTO CLAMP (DAC)

■ Improvementof Productivity through the Memory Function

10 combinations of set values of parameters of

The primary pressure for wax injection (Press 1),

Secondary pressure for wax injection (Press 2),

Secondary pressure start time (Time),

Mold clamping pressure (Clamp),

Forward pressure (Forward) and hold time (Hold) can be stored in memory.

It is possible not only to decrease the number of defective products but alsogreatly enhance working

efficiency by storing the conditions suitable for a rubber mold in memory.

■ Improvement of Operability

Puta rubber mold on the rubber mold holder, input the memory number and push the startbutton, and one cycle of ‘mold clamping→nozzle guidance→vacuum wax injection→hold→releaseof mold clamp’ is automatically operated.

■ Indication of Remaining Amount of Wax

Theamount of wax remaining in the tanks is indicated with an accuracy of 1%.

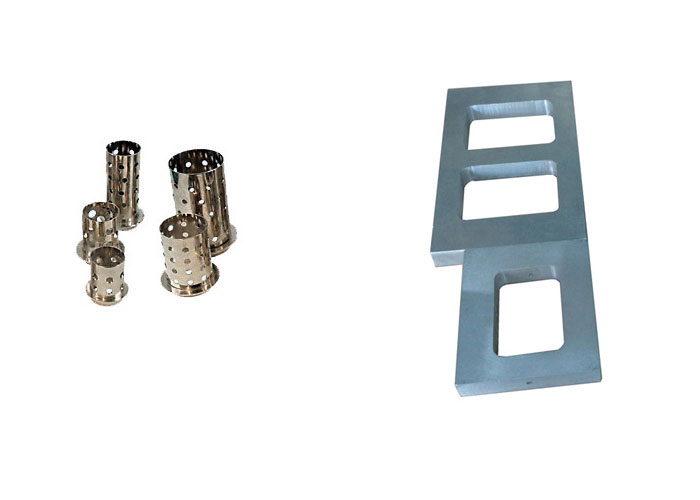

■ It’s possible to change the LargeClamp

■ Height Adjuster Debut!!

It is easy to change the height.

Technical data

|

Power supply |

AC 100-240 V, 50/60 Hz, single phase |

||

|

Power consumption |

50 VA |

||

|

Air supply source |

0.4 MPa or more, |

||

|

Setting range of regulator : 0.25-0.30 MPa |

|||

|

Clamp |

Rubber mold size(MAX) |

Normal |

80(W)× 90(D)×40(H) |

|

Large |

125(W)×150(D)×50(H) |

||

|

Dimension |

Normal |

150(W)×157(D)×223(H) |

|

|

Large |

190(W)×196(D)×223(H) |

||

|

Indication range of pressure sensor |

-30 ~ + 500 kpa |

||

|

Setting range of primary pressure |

10~220 kpa |

||

|

Setting range of secondary pressure |

10~220 kpa |

||

|

Setting range of secondary |

0 ~ 99.9 sec |

||

|

Setting range of mold clamping pressure (CLAMP) |

30~235 kpa |

||

|

Setting range of clamping hold time (HOLD) |

0~300 sec |

||

|

Setting range of forward pressure (FORWARD) |

30~235 kpa |

||

|

Setting range of vacuuming time (VACUUM) |

0~99.9 sec |

||

|

Setting range of injection time (INJECTION) |

0~99.9 sec |

||

|

Counter |

9999 counts |

||